3D Printer

Field reports about Prusa i3 based FDM printers

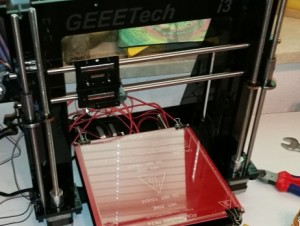

Field report: 3D printer - Geeetech Prusa i3 pro B

3D printer kits have become affordable. The new hobby can be purchased for under 200$. What you buy is a device that initially consumes a lot of time, but offers completely new possibilities. Once the printer is assembled, it's time for fine-tuning. I spent some time to choose the right software (Slicer) and to understand the different setting parameters. In addition to the kits, there are also pre-assembled models, which can save quite a bit of time during commissioning. In addition, the standa... ... continue reading

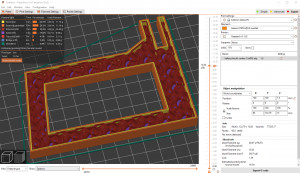

free slicer comparison: PrusaSlicer vs Cura vs Slic3r

I have used 2 different slicers extensively so far: Cura and PrusaSlicer. Both slicers are free, both deliver usable results with the manufacturer's default settings, both have their strengths and hardly any weaknesses. ... continue reading

Top useful and less useful 3D models

Why do I need a 3D printer? Admittedly, I also asked this question when I first heard about affordable 3D printers for the home. After a few years of use, this is how I would describe it: Even now, I don't know what I'll need the printer for next, but I know what I can do with it and I know: I'll need it again: at the latest, when a plastic part breaks somewhere, I think about whether I can print a replacement part myself ... ... continue reading

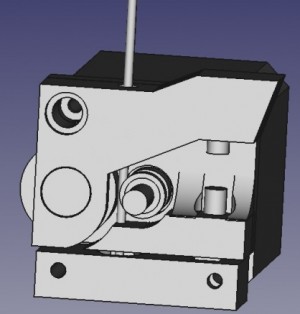

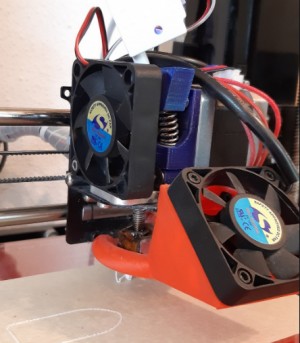

3D: direct extruder drive self printed

I wanted to provide the extruder stepper motor with a smaller drive gear so that this brings a little more force on the filament and clogs the nozzle less easily. When using a smaller gear, the position of the direct extruder MK8 no longer fits, so I redesigned, printed and replaced the parts around the stepper motor. As material I used PETG, because PETG tolerates a bit more temperature compared to PLA. I was able to successfully test printing with temperatures up to 260° with the setup. ... continue reading

3D Printer Caution Fire Hazard

The 3D printer as a potential cause of fire: I had read about this and also thought about it, but in the wrong place. ... continue reading

Prusa i3 based printers: improvements and adjustments

Entry-level printers, such as the GEEETech i3 pro B, are a solid starting point, but have the potential for improvement in some areas. Certain modifications can improve security and print quality, as well as functionality: ... continue reading

OctoPi Installation - 3D-Printer Webinterface

A Raspberry Pi with OctoPi installed offers a very easy way to upgrade existing 3D printers. ... continue reading

Glasses from the 3D printer

But I only wanted to clean them with a soft cloth and I already had 2 parts in my hand. After about 3 years it is broken: the frame of my glasses is broken. ... continue reading

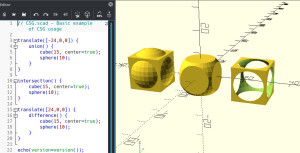

free 3D programs in comparison FreeCAD vs. OpenSCAD vs. Blender

The available CAD programs with OpenSource license can't really keep up with paid products of other manufacturers, nevertheless the thought to get along without license motivates me and therefore to rely on open source software. Starting with OpenSCAD, I later ended up with FreeCAD and Blender. ... continue reading